Why Zinc? And Why Die Castings?

Zinc die casting alloys are versatile engineering materials. No other alloy system provides the combination of strength, toughness, rigidity, bearing performance and economical Castability. Listed are zinc alloy attributes, which can reduce component costs. Improving precision, quality and product performance are other zinc alloy design advantages.

Precision Tolerances Zinc die casting alloys are castable to closer tolerances than other metals or moulded plastics, therefore presenting the opportunity to reduce or eliminate machining. "Net Shape" or "Zero Machining" manufacturing is a major advantage of zinc die casting.

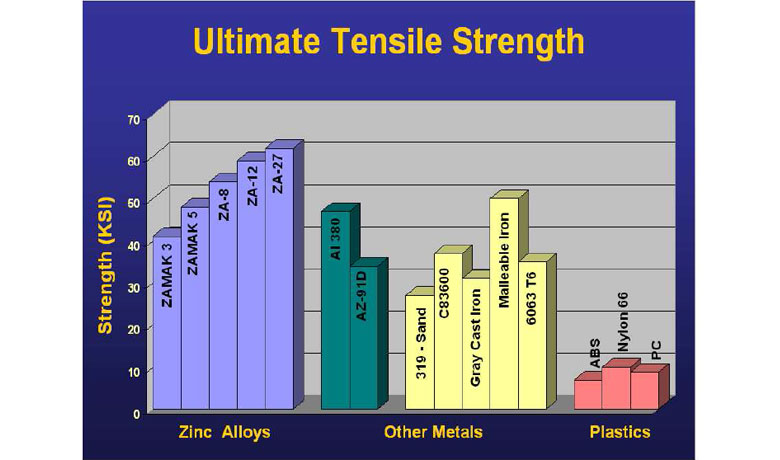

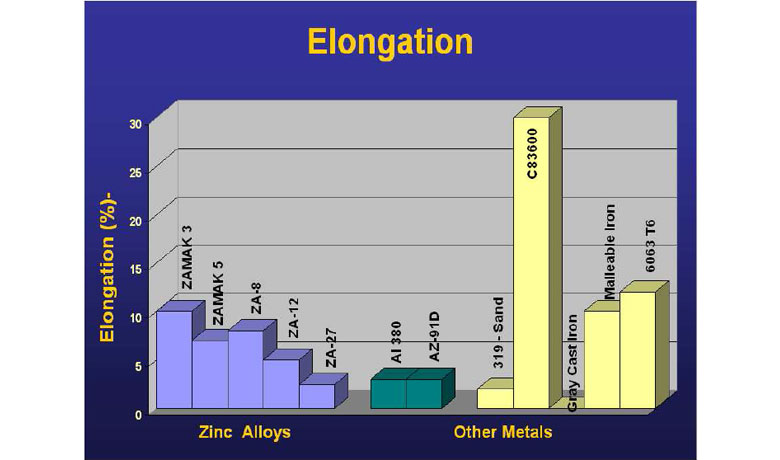

Strength and Ductility Zinc die casting alloys offer high strengths (to 60,000 psi) and superior elongation for strong designs and formability for bending, crimping and riveting operations. Detailed mechanical properties listed below.

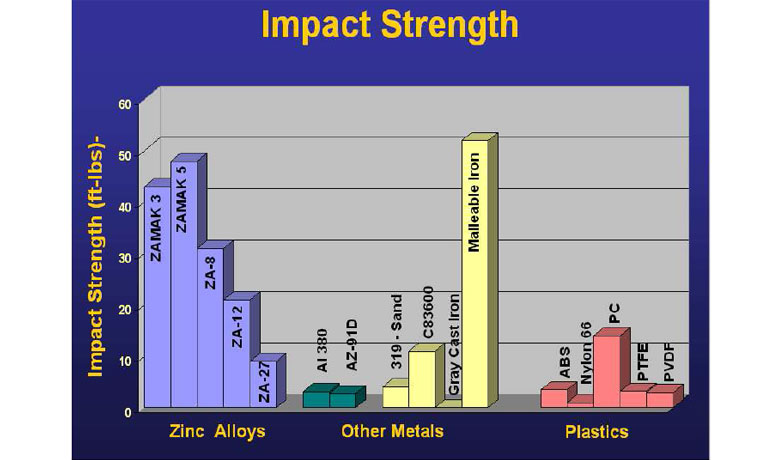

Toughness Few materials provide the strength and toughness of zinc alloys. Impact resistance is significantly higher than cast aluminium alloys, plastics and grey cast iron.

Rigidity Zinc alloys are rigid engineering materials. Their elastic module are greater than those of aluminium and magnesium alloys and an order of magnitude greater than those of engineering plastics. Thus, combined with their high strength allows the volume of individual castings to be markedly reduced, saving space and weight.

Anti-Sparking Zinc die cast alloys are non sparking and suitable for hazardous location applications such as coal mines, tankers and refineries.

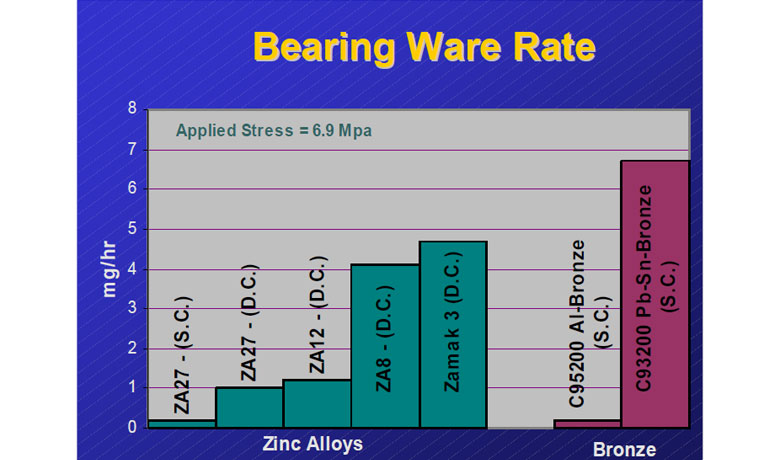

Bearing Properties Bushing and wear inserts in component designs can often be eliminated because of zinc's excellent bearing properties. For example, zinc alloys have outperformed bronze in heavy- duty industrial applications.

Easy Finishing Zinc castings are readily polished, plated, painted, chromated or anodized for decorative and/or functional service.

Thin Wall Castability Exceptional casting fluidity is displayed by all ZAMAC alloys, which provides superior thin-wall Castability. Wall thicknesses of 0.025 inches (0.635 mm) for die casting are produced. This thin-wall capability results in smaller, lighter, low cost components.

Machinability Fast, trouble-free machining characteristics of zinc materials minimize tool wear and machining costs.

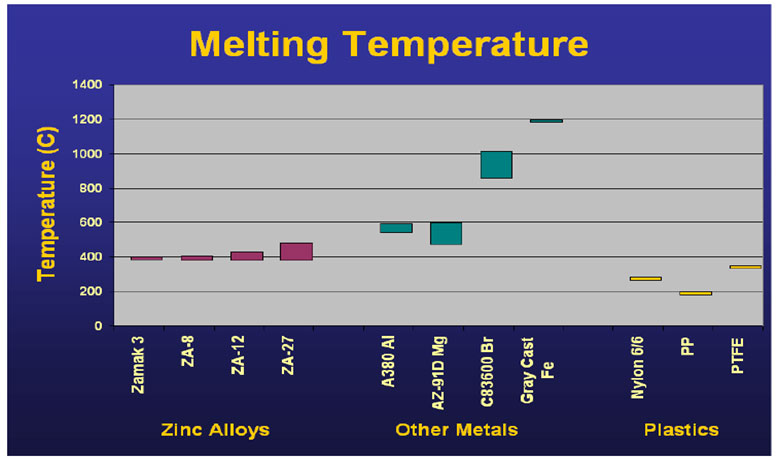

Low Energy Costs Because of their low melting temperature, zinc alloys require less energy to melt and cast versus other engineering alloys.

Long Tool Life Low casting temperatures result in minimal thermal shock and therefore extended life for die casting tools. For example, tooling life can be more than 10 times that of aluminium dies.

Clean and Recyclable Zinc die cast alloys are among the cleanest melting materials available. Zinc metal is non-toxic and scrap items are a reusable resource, which are efficiently recycled.

Zinc Alloys for Die Castings in detail

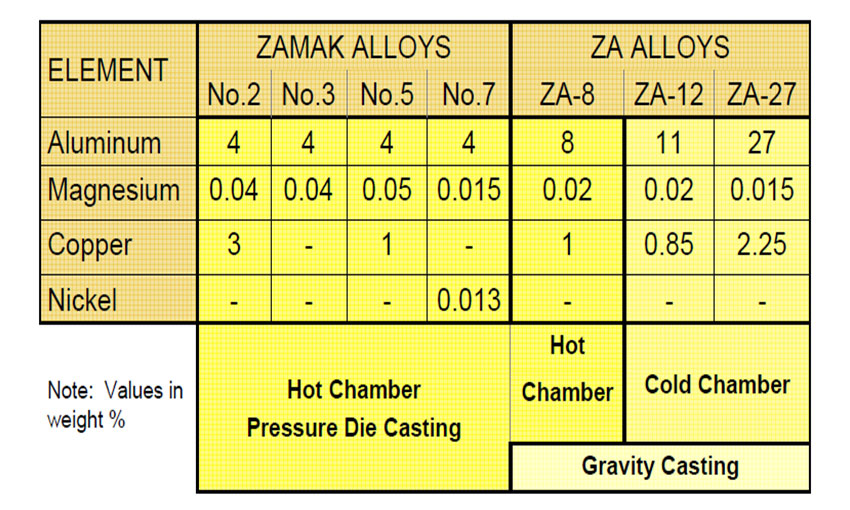

Zinc alloys are divided into two grades.

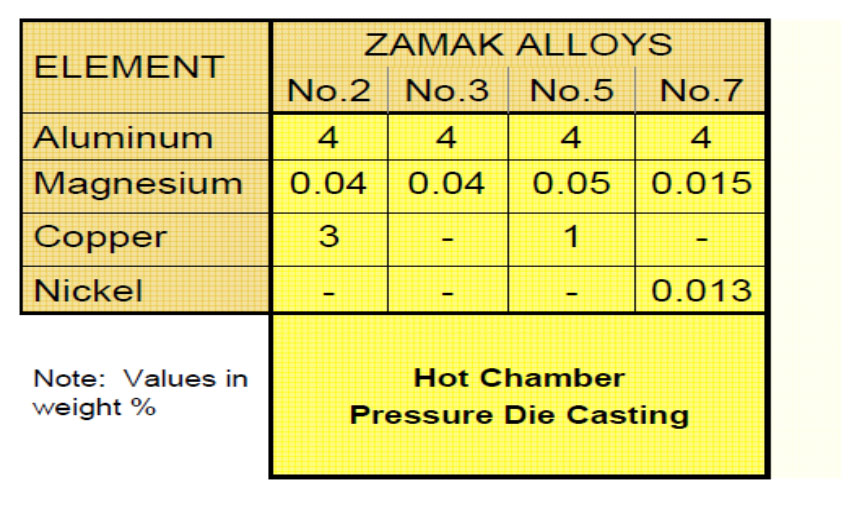

- Zamak alloys.

- ZA alloys.

Zinc die castings mainly made in zinc based alloys ie: Zamak 3, Zamak 5. And also there are less in percentage of Zamak 2,Zamak 7 and ZA 8 are being used for special applications.

Mechanical and chemical properties of both alloy details given below.

Zinc Alloys – ZAMAK Grades

ZAMAK 3 Alloy

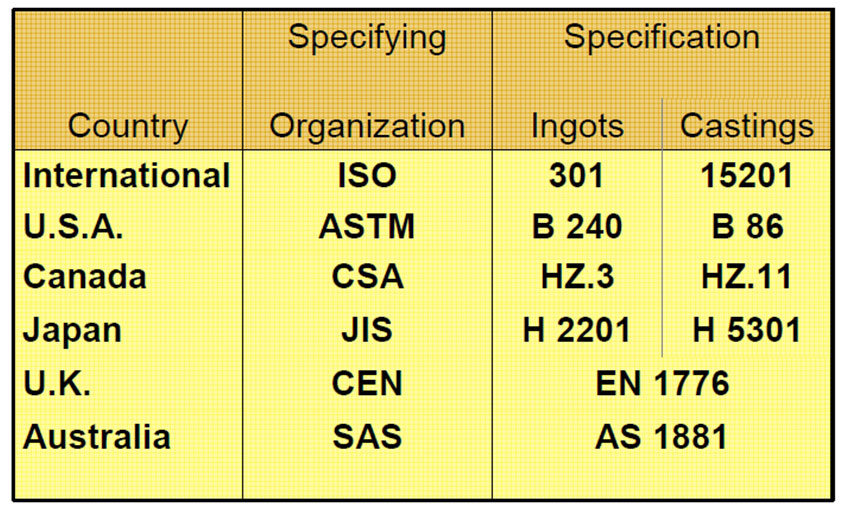

Zinc Alloys All Grades Composition

Selection of Zinc Alloys Properties of zinc Die Castings

© Copyright 2018. All Rights Reserved.